Application Scope of GICL & GIICL Series Drum Gear Couplings

Application Scope of GICL & GIICL Series Drum Gear Couplings

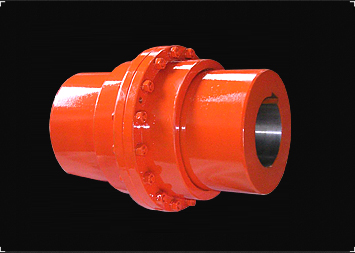

1. Overview

Drum gear couplings (rigid flexible couplings) consist of internal gear rings and flanged half-couplings with external teeth, both sharing identical tooth counts. The external teeth are categorized as straight teeth or drum-shaped teeth. Compared to straight-tooth designs, drum-shaped teeth enable:

•Larger angular displacement tolerance

•Improved tooth contact conditions

•Enhanced torque transmission capacity

•Extended service life

2. Technical Features of GICL/GIICL Series

•Optimized for low-speed, heavy-load conditions

•Robust construction with high misalignment compensation (axial, radial, angular)

•Sealed lubrication system to minimize wear and ensure stable performance

3. Key Applications

GICL/GIICL series couplings are widely used in industries requiring reliable heavy-duty power transmission, including:

•Metallurgy: Rolling mills, blast furnace equipment

•Mining: Crushers, conveyors, hoisting systems

•Material Handling: Cranes, winches, heavy-duty transporters

•Petrochemical: Pumps, compressors, agitators

•General Machinery: High-torque drives in manufacturing and processing systems

4. Industry Advantages

•Durability: Designed to withstand harsh environments (shock loads, vibrations, temperature variations).

•Versatility: Suitable for both horizontal and vertical shaft configurations.

•Maintenance Efficiency: Modular design simplifies inspection and replacement.

https://www.timothyholding.com/Application-of-GICL-GIICL-Drum-Gear-Couplings.html